Check out the TennMax RF Absorber Sheets. Available from design to cutting in all locations. Learn More

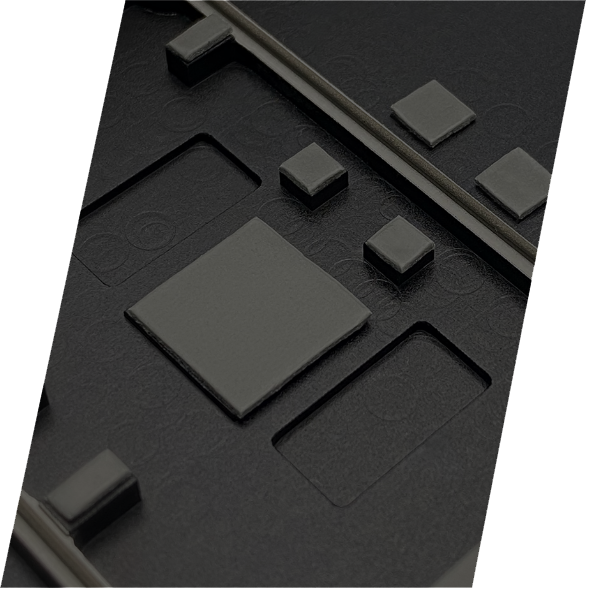

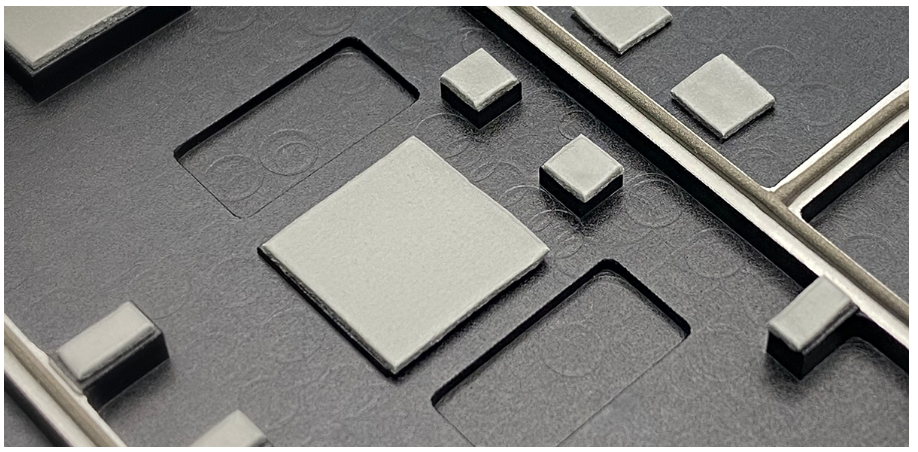

Thermal Interface Materials are specially treated high performance silicone elastomers. They are embedded with thermal conductive particles, creating a conforming filler for the gaps between thermal transfer surfaces, such as between microprocessors and heat sinks. Below is a glance of our Thermal Interface Materials:

GP-IP pads are ideal for applications where thermal conductive, electrical insulating, and strong mechanical properties are required.

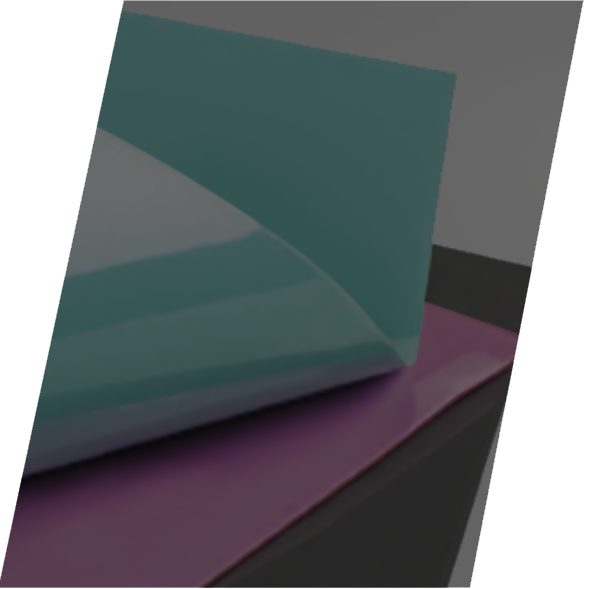

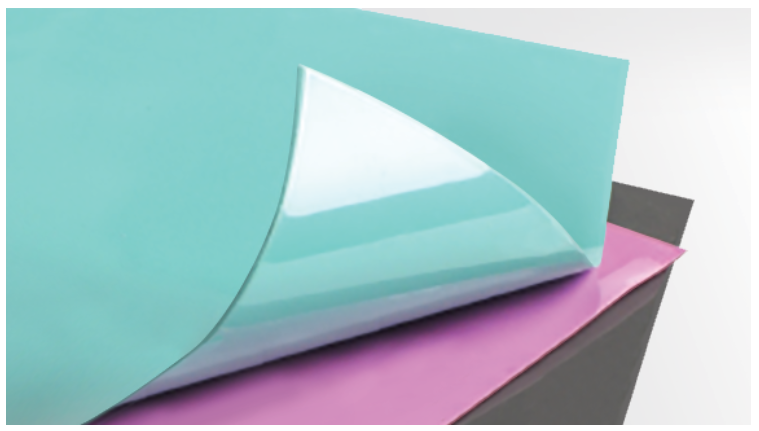

Designed to replace conventional thermal pads, these jellies save assembly time and reduce labor costs. Ultra soft and highly compressible properties protect force-sensitive components.

Can accurately place beads as small as 0.25 mm high. Through vigorous testing and rapid prototyping, we work with customers to overcome any accuracy challenge.

Multi-layer forming technology helps to get the balance of performance and handling while enabling engineers in design flexibility.

GP-IP pads are designed for applications where thermal conductive, electrical insulative, and strong mechanical properties are required.

| Typical Properties | THERMALLY CONDUCTIVE PADS | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Part Number | GP1000 | GP2000 | GP3000 | GP5000 | GP6000 | GP7000 | GP8000 | GP8000HI | GPE000 | GPE000HI | GPG000 | GPM000 |

| Standard Softness (H1) | 46 Shore OO | 46 Shore OO | 70 Shore OO | 70 Shore OO | ||||||||

| Ultrasoft Softness (HO) | N/A | 36 Shore OO | N/A | N/A | ||||||||

| Übersoft Softness (HU) | N/A | 26 Shore OO | N/A | N/A | ||||||||

| Thermal Conductivity | 1.0 W/m-K | 1.5 W/m-K | 2.0 W/m-K | 3.0 W/m-K | 6.0 W/m-K | 5.0 W/m-K | 7.8 W/m-K | 7.8 W/m-K | 11.0 W/m-K | 11.0 W/m-K | 13.0 W/m-K | 15.0 W/m-K |

| Thickness | 0.13 mm to 10 mm | 0.25 mm to 10 mm | 0.25 mm to 5 mm | |||||||||

| Dielectric Strength | 20 kVac/mm | 10 kVac/mm | 20 kVac/mm | 10 kVac/mm | 10 kVac/mm | 10 kVac/mm | 100 Vac/mm | 10 kVac/mm | 50 Vac/mm | 8 kVac/mm | 5 kVac/mm | 5 kVac/mm |

| Operating Temperature | -55 to 200 °C | |||||||||||

| Flammability Rating | 94V-O | |||||||||||

| Composition | Filled silicone elastomer sheet | |||||||||||

| Color | Light Gray | Blue | Gray | Light Blue | Light Gray | Cyan | Light Gray | Light Gray | Light Gray | Light Gray | Gray | Gray |

| Typical Properties | THERMALLY CONDUCTIVE HIGH VOLTAGE INSULATIVE PADS | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Part Number | GP-IP1000 | GP-IP1500 | GP-IP2800 | GP-IP3800 | GP-IP5000 | ||||||||||

| GP-IP1025 | GP-IP1035 | GP-IP1050 | GP-IP1525 | GP-IP1535 | GP-IP1550 | GP-IP2825 | GP-IP2835 | GP-IP2850 | GP-IP3825 | GP-IP3835 | GP-IP3850 | GP-IP5025 | GP-IP5035 | GP-IP5050 | |

| Softness | 70 Shore A | 70 Shore A | 70 Shore A | 70 Shore A | 70 Shore A | ||||||||||

| Thermal Impedance @ 50 psi | 0.64 °С-in²/W | 0.79 °С-in²/W | 0.90 °С-in²/W | 0.58 °С-in²/W | 0.62 °С-in²/W | 0.68 °С-in²/W | 0.48 °С-in²/W | 0.52 °С-in²/W | 0.59 °С-in²/W | 0.44 °С-in²/W | 0.49 °С-in²/W | 0.54 °С-in²/W | 0.40 °С-in²/W | 0.45 °С-in²/W | 0.48 °С-in²/W |

| @ 345 KPa | 4.12 °С-cm²/W | 5.10 °С-cm²/W | 5.78 °С-cm²/W | 3.75 °С-cm²/W | 3.99 °С-cm²/W | 4.38 °С-cm²/W | 3.09 °С-cm²/W | 3.35 °С-cm²/W | 3.80 °С-cm²/W | 2.84 °С-cm²/W | 3.13 °С-cm²/W | 3.48 °С-cm²/W | 2.59 °С-cm²/W | 2.90 °С-cm²/W | 3.09 °С-cm²/W |

| Thermal Conductivity | 1.0 W/m-K | 1.5 W/m-K | 2.8 W/m-K | 3.8 W/m-K | 5.0 W/m-K | ||||||||||

| Thickness | 0.25 mm | 0.35 mm | 0.50 mm | 0.25 mm | 0.35 mm | 0.50 mm | 0.25 mm | 0.35 mm | 0.50 mm | 0.25 mm | 0.35 mm | 0.50 mm | 0.25 mm | 0.35 mm | 0.50 mm |

| Dielectric Constant @ 1MHz | 3.2 | 3.3 | 3.2 | 3.2 | 3.4 | ||||||||||

| Operating Temperature | -55 to 200 °C | -55 to 200 °C | -55 to 200 °C | -55 to 200 °C | -55 to 200 °C | ||||||||||

| Flammability Rating | 94V-O | 94V-O | 94V-O | 94V-O | 94V-O | ||||||||||

| Composition | Fiberglass reinforced silicone | Fiberglass reinforced silicone rubber | Fiberglass reinforced silicone rubber | Fiberglass reinforced silicone | Fiberglass reinforced silicone rubber | ||||||||||

| Color | Blue | Gray | Light Blue | Magenta | Cyan | ||||||||||

| Typical Properties | THERMALLY CONDUCTIVE DISPENSABLE JELLIES | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Part Number | GP3F7120 | GP5F7121 | GP7F7123 | GP8F7125 | GP8F7125HI | GP8F7125HI-20 microns | GPEF7126 | GPEF7126HI | GPEF7126HI-20 microns | |

| Softness | 5 Shore OO | 10 Shore OO | 8 Shore OO | 10 Shore OO | 10 Shore OO | 10 Shore OO | 10 Shore OO | 10 Shore OO | 10 Shore OO | |

| Thermal Impedance @ 50 psi | 0.068°С-in²/W | 0.061 °С-in²/W | 0.056 °С-in²/W | 0.059 °С-in²/W | 0.041 °С-in²/W | 0.036 °С-in²/W | 0.039 °С-in²/W | 0.051 °С-in²/W | 0.029 °С-in²/W | |

| Thermal Conductivity | 2.0 W/m-K | 3.0 W/m-K | 5.0 W/m-K | 8.0 W/m-K | 8.0 W/m-K | 8.0 W/m-K | 11.0 W/m-K | 11.0 W/m-K | 11.0 W/m-K | |

| Dielectric Strength | >8000 Volt/mm | >8000 Volt/mm | >8000 Volt/mm | N/A | >10000 Volt/mm | >4500 Volt/mm | N/A | >4500 Volt/mm | >6000 Volt/mm | |

| Operating Temperature | -55 to 200 °C | |||||||||

| Density | 2.80 g/cm³ | 3.00 g/cm³ | 3.20 g/cm³ | 2.30g/cm³ | 3.20 g/cm³ | 3.20 g/cm³ | 2.35 g/cm³ | 3.20 g/cm³ | 3.15 g/cm³ | |

| Composition | Silicone Gel | |||||||||

| Color | Black | Brick Red | Gray | Gray | Light Gray | Dark Gray | Gray | Dark Gray | Dark Gray | |