Check out the TennMax RF Absorber Sheets. Available from design to cutting in all locations. Learn More

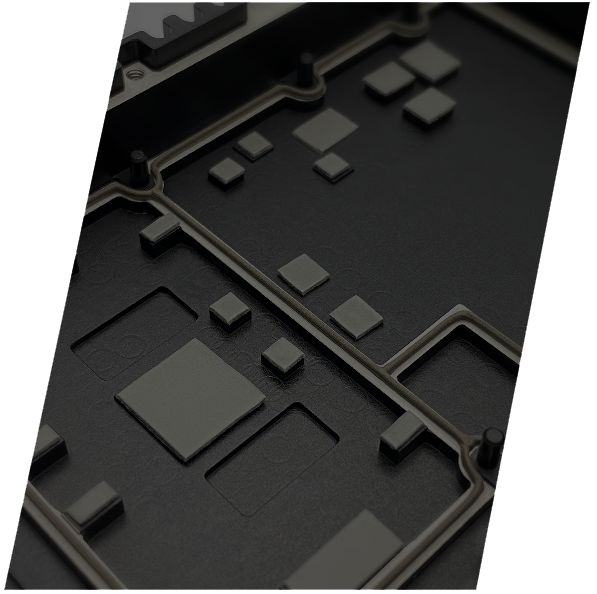

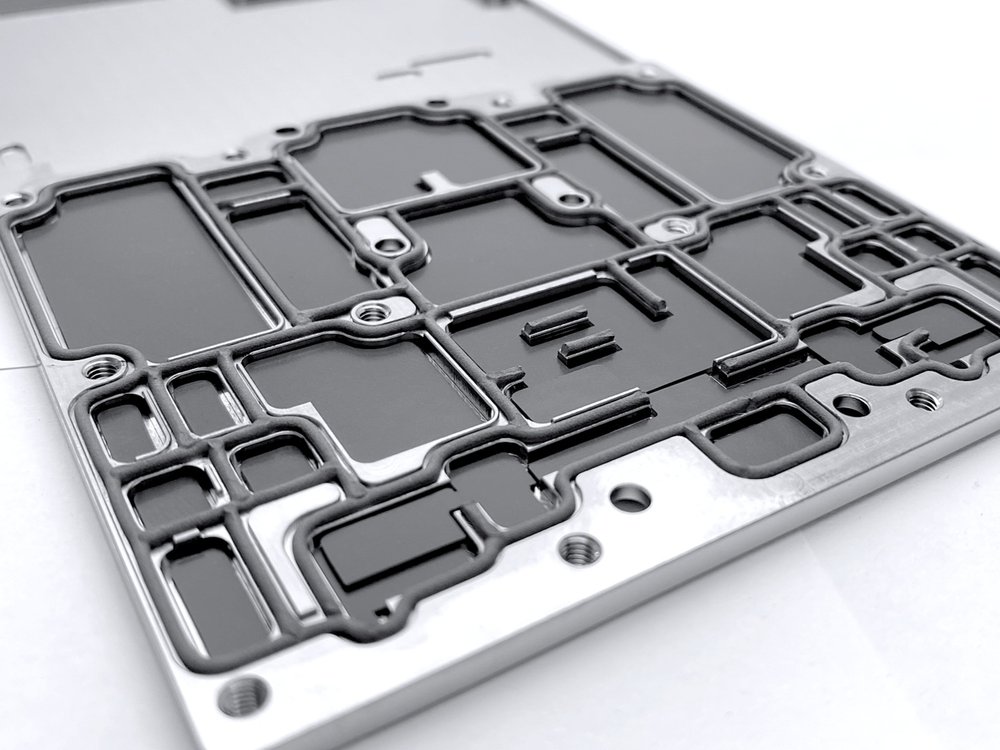

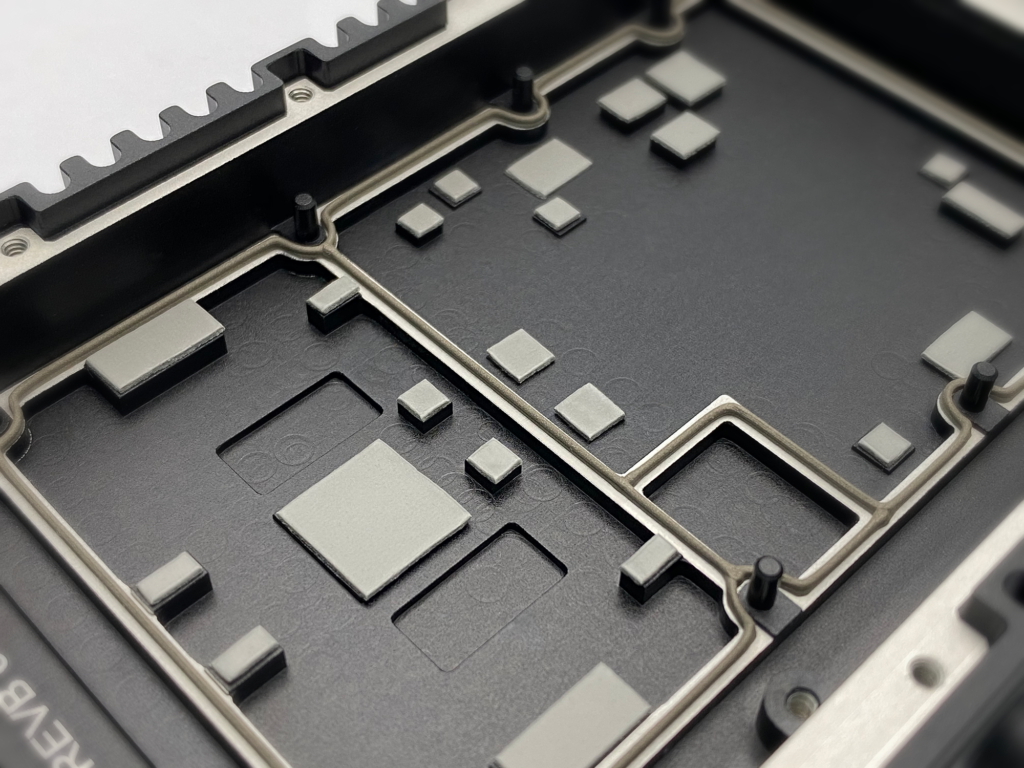

One of our bestsellers – through rapid prototyping, our team designs FIP gaskets that reduce the amount and the size of screw holes to achieve smaller overall packaging. In addition, our FIP can be placed on PCB traces as thin as 0.5mm, creating more space for board components.

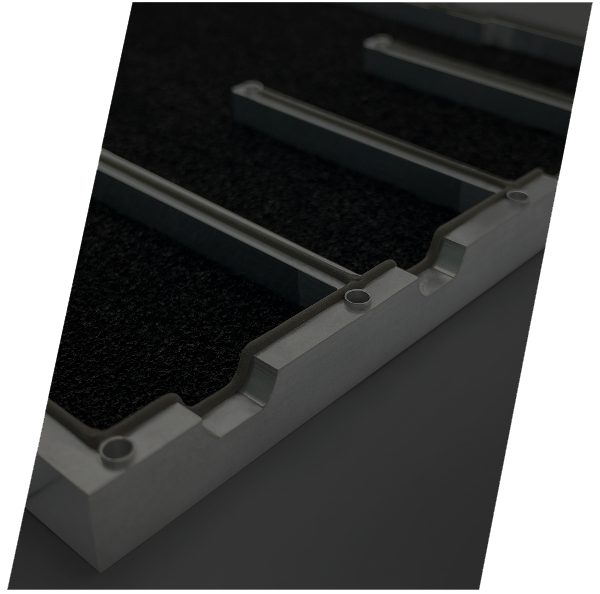

Filled with Nickel/Graphite, Ag/Cu, Ag/Al, Ag/Ni or other conductive particles, providing excellent electrical conductivity.

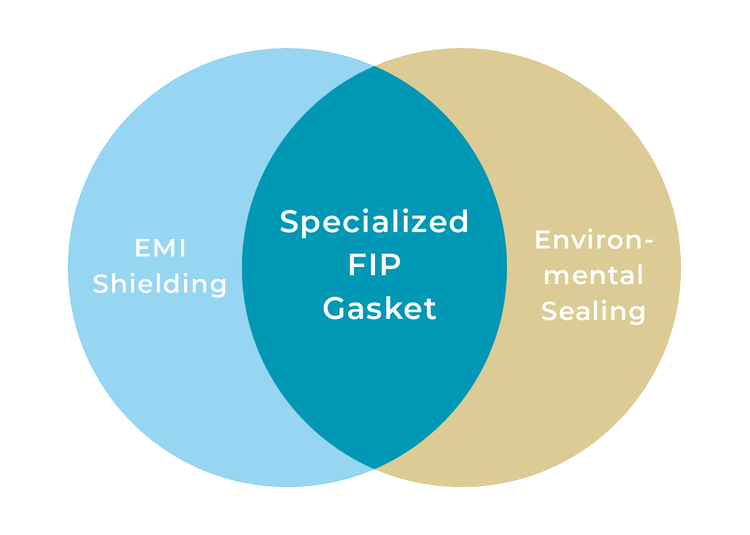

Unique conductive gasketing materials for specialty applications:

Silicone and fluorosilicone Form-in-Place gaskets designed for protection up to an IP68 rating.

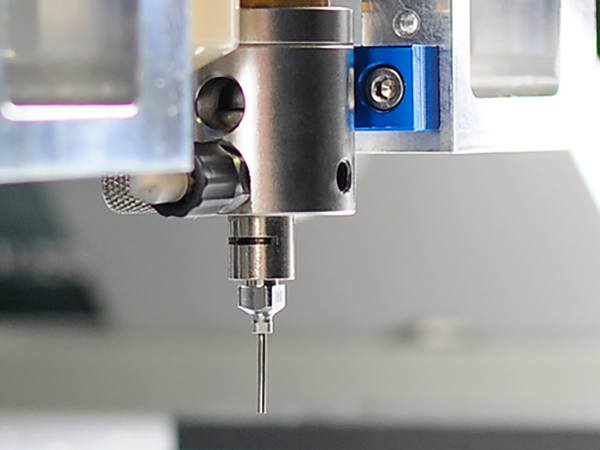

Can accurately place beads as small as 0.25 mm high. Through vigorous testing and rapid prototyping, we work with customers to overcome any accuracy challenge.

Our shielding solutions are consistently tested with outstanding results.

Let’s get down to the details.

ISO 9001 and AS 9100 Certified. ITAR Registered.

Cybersecurity Maturity Model Certification (CMMC) / SP NIST 800-171 Compliant. Learn More →

| Typical Properties | EMI SHIELDING GASKETS | ENVIRONMENTAL SEALING GASKETS | EMI SPECIALTY GASKETS | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Part Number | F5301 | F5304 | F5314 | F5221 | F5321 | F5521 | F6003 | F6081 | F7101 MaxTEC™ | F5381 Chemical Resistance | F5382 Chemical Resistance | F9304 MaxEEC™ |

| Elastomer Binder | Silicone | Fluorosilicone | Silicone | Fluorosilicone | Silicone | |||||||

| Conductive Filler | Ni/Gr | Ag/Cu | Ni/Gr | Ag/Al | Special Fillers | Ni/Gr | ||||||

| Curing System | Thermal | Moisture | Thermal | Thermal | Thermal | |||||||

| Hardness (Shore A) | 75 | 30 | 35 | 40 | 70 | 55 | 40 | 40 | 55 | 60 | 75 | 35 |

| Resistance * (Ohm) | 0.05 | 0.08 | 0.1 | 0.05 | 0.09 | 0.07 | 0.10 | 0.09 | 0.10 | 0.15 | 0.06 | 0.06 |

| Shielding Effectiveness | > 100 dB @ 200 Mhz - 40 GHz | > 100 dB @ 200 Mhz - 40 GHz | ||||||||||

| Minumum Bead Height | 0.3 mm | 0.3 mm | 0.3 mm | 0.5 mm | 0.3 mm | 1 mm | 0.3 mm | |||||

| Features | Small bead application with superior adhesion | Ultrasoft, low compression force application | Soft, reboundable, low compression force application for higher frequencies | Superior conductivity with higher compression capabilities | Preferred material for metalized plastics, RTV version of F5301 | High corrosion resistance in harshest environments | UV Resistant | Resistance to polar solvents, fuels, chemicals, and salt spray/fog with low outgassing | Over 2x the thermal conductivity of standard FIP EMI gaskets | Resistance to polar solvents, fuels, oil additives, chemicals, and salt spray/fog with low outgassing | Excellent EMI shielding performance with superior environmental sealing property | |