Check out the TennMax RF Absorber Sheets. Available from design to cutting in all locations. Learn More

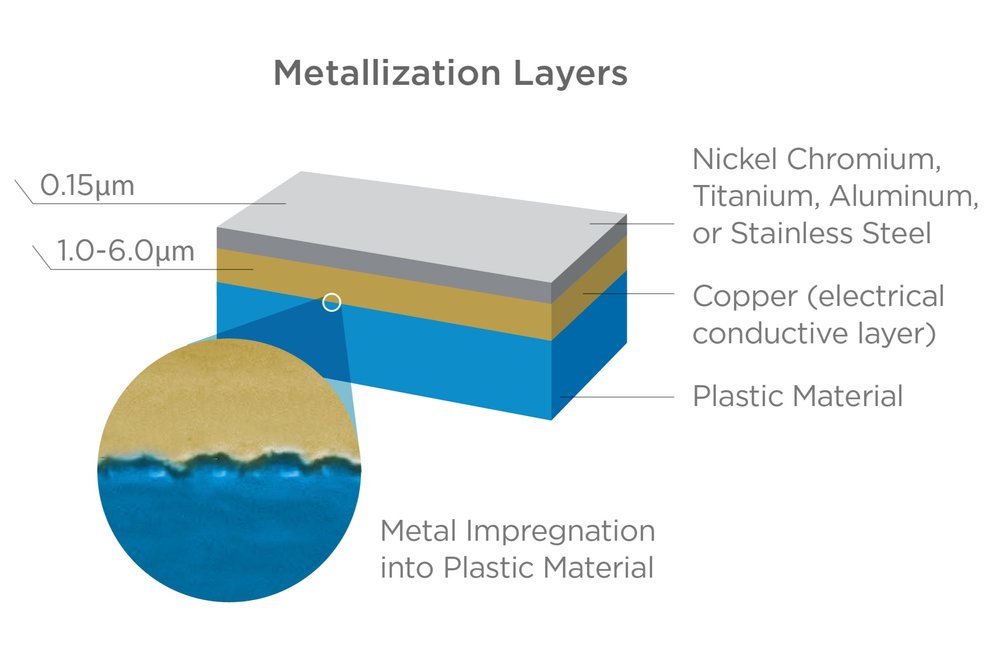

Vacuum Metallization, also known as Physical Vapor Deposition (PVD), is the process specifically designed for EMI shielding, where a metallic layer, such as titanium, copper, or aluminum is deposited onto a wide range of plastic housing, such as ABS, PC, PA6, PBT, PPA, PPS, PEI, PET, PSU or PEEK.

This process is a cost-effective way of shielding against electromagnetic interference, providing a wide range of material choices.

Within the vacuum chamber, the metal is heated and vaporized, then impregnated onto the plastic housing.

Our facilities are uniquely equipped with Evaporation and Sputtering technologies, both are done in a single vacuum chamber.

This process produces a thicker shielding layer and higher level of accuracy across the production line, ensuring high quality end products while maximizing production yield.

The metallization by vacuum technology uses the condensation of a metal vapor coating the object. This vapor is generated within a vacuum and diffuses within the vacuum. The standard thickness of the metallic layer is 1.6 microns with the possibility of up to 10 microns.